|

NANTONG JUGAO MACHINERY CO LTD

|

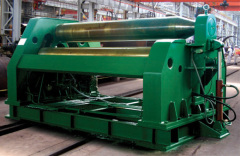

iron sheet rolling machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

This machine is four rollers rolling machine. It is controlled by computer. It with pr-bend ing capacity, Feeding plate and don't need

Product Name :4 rollers rolling machine

Control:CNC

Max rolling thickness:50mm

Max rolling length:3000mm

ELECTRICAL EQUIPMENTS:SIEMENS

ROLLER MATERIAL:9Crsi

QUALITY CERTIFICATION:CE

WARRANTY:100% one year

i. This machine is four rollers rolling machine. It is controlled by computer. It with pr-bend ing capacity, Feeding plate and don't need return. So it pr-bend the ends of plate and roll shape just one time.

ii. The four working rollers do forge and do material treatment, HB220~260, combination mechanical performance is good, the strength is high, friction endurance is high, so it suit high load work and have long life.

iii. The work roller end bearing adopt roller bearing, so it has small friction coefficient, decrease reactive power loss, reduce energy consumption.

iv. Lifting move of bottom roller and sides rollers controlled by computer, automatic leveling, show as figure at the same time. The synchronized precision ±0.2mm. Plate bending high-precision, easy to use

v. This machine has removable console, the operator more convenient to use, touch-screen display the location of three work rollers, so that the operator at a glance.

vi. The machine control system using Japan's OMRON intelligent high-speed PLC programmable logic controller, the system has a fault diagnosis, intelligent judge error, machine tool parts of the monitoring, processing logic, memory, such as power protection; the system with anti-jamming capability Strong, long service life, earthquake, etc. stable.

vii. The sensors of bottom and side rollers has high accuracy ,to ensure position accuracy and monitor the roller position.

viii. The strong power part components choose from Suzhou Electrical. So it has some advantages, long life, trouble-free for a long time, and so on.

ix. The valve block of hydraulic system selected from north-Taiwan Seiki products.This valve block has some advantages, over-charge is big, a small resistance and pressure, hot loss is small, so the function is reliable.

x. Hydraulic pipe joint use of new technologies used in the metallurgical and mining equipment joint fast, reliable connection to the radial seal to ensure that the equipment in the hydraulic system does not work in oil.

xi. Hydraulic suction system has oil back and oil filter to ensure the system clean , and has air filter to ensure the fuel tank normal respiration and evaporation of water. there is a two-channel safety protect devices in the system to ensure normal use of equipment.

Control:CNC

Max rolling thickness:50mm

Max rolling length:3000mm

ELECTRICAL EQUIPMENTS:SIEMENS

ROLLER MATERIAL:9Crsi

QUALITY CERTIFICATION:CE

WARRANTY:100% one year

i. This machine is four rollers rolling machine. It is controlled by computer. It with pr-bend ing capacity, Feeding plate and don't need return. So it pr-bend the ends of plate and roll shape just one time.

ii. The four working rollers do forge and do material treatment, HB220~260, combination mechanical performance is good, the strength is high, friction endurance is high, so it suit high load work and have long life.

iii. The work roller end bearing adopt roller bearing, so it has small friction coefficient, decrease reactive power loss, reduce energy consumption.

iv. Lifting move of bottom roller and sides rollers controlled by computer, automatic leveling, show as figure at the same time. The synchronized precision ±0.2mm. Plate bending high-precision, easy to use

v. This machine has removable console, the operator more convenient to use, touch-screen display the location of three work rollers, so that the operator at a glance.

vi. The machine control system using Japan's OMRON intelligent high-speed PLC programmable logic controller, the system has a fault diagnosis, intelligent judge error, machine tool parts of the monitoring, processing logic, memory, such as power protection; the system with anti-jamming capability Strong, long service life, earthquake, etc. stable.

vii. The sensors of bottom and side rollers has high accuracy ,to ensure position accuracy and monitor the roller position.

viii. The strong power part components choose from Suzhou Electrical. So it has some advantages, long life, trouble-free for a long time, and so on.

ix. The valve block of hydraulic system selected from north-Taiwan Seiki products.This valve block has some advantages, over-charge is big, a small resistance and pressure, hot loss is small, so the function is reliable.

x. Hydraulic pipe joint use of new technologies used in the metallurgical and mining equipment joint fast, reliable connection to the radial seal to ensure that the equipment in the hydraulic system does not work in oil.

xi. Hydraulic suction system has oil back and oil filter to ensure the system clean , and has air filter to ensure the fuel tank normal respiration and evaporation of water. there is a two-channel safety protect devices in the system to ensure normal use of equipment.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Rolling Machine

Thread Rolling Machine

Steel Rolling Machine

Plate Rolling Machine

Hydraulic Rolling Machine

Rolling Bag Making Machine

More>>

.jpg)