|

NANTONG JUGAO MACHINERY CO LTD

|

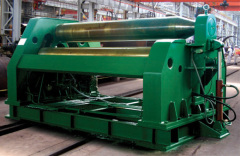

3 Hydraulic rollers machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

3 Hydraulic rollers machine

The upper roller can move vertically as well as horizontally.

3 Hydraulic rollers machine

1. The upper roller can move vertically as well as horizontally.

2. The end pre-bending is finished with high precision by moving the upper roller and making it unsymmetrical position with two lower rollers.

3. Two lower rollers are driven by the motor and decelerator for rolling the plate.

4. It is convenient & safe for feeding and operating because of the constant altitude of the lower rolls.

5. It is controlled by PLC, and the positioning of the rolls is digital readout.

6. The upper roller is in the shape of drum, accompany of the support rolls of two lower rollers for up & down adjustment, it can get the high precision for deviation from straightness of the finished products.

7. It adopts the rear rolling to gain the high precision for the circularity of the finished products.

8. The feeding direction and the moving direction of the top roll are opposite.

9. The upper roller press down, meanwhile the lower rollers rotate for the continuous bending.

10. The end pre-bending is accomplished by the direct pressure from the upper roller so as to avoid the "angle of relief" of bending, at the same time; it can control the length and shape of the flat end.

11. This kind of Plate Rolls Bending Machine also can roll cone shape which is optional.

1. The upper roller can move vertically as well as horizontally.

2. The end pre-bending is finished with high precision by moving the upper roller and making it unsymmetrical position with two lower rollers.

3. Two lower rollers are driven by the motor and decelerator for rolling the plate.

4. It is convenient & safe for feeding and operating because of the constant altitude of the lower rolls.

5. It is controlled by PLC, and the positioning of the rolls is digital readout.

6. The upper roller is in the shape of drum, accompany of the support rolls of two lower rollers for up & down adjustment, it can get the high precision for deviation from straightness of the finished products.

7. It adopts the rear rolling to gain the high precision for the circularity of the finished products.

8. The feeding direction and the moving direction of the top roll are opposite.

9. The upper roller press down, meanwhile the lower rollers rotate for the continuous bending.

10. The end pre-bending is accomplished by the direct pressure from the upper roller so as to avoid the "angle of relief" of bending, at the same time; it can control the length and shape of the flat end.

11. This kind of Plate Rolls Bending Machine also can roll cone shape which is optional.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

3-In-1 Machine

Hydraulic Machine

Hydraulic Cutting Machine

Hydraulic Press Machine

Hydraulic Shearing Machine

Hydraulic Bending Machine

More>>

.jpg)