|

NANTONG JUGAO MACHINERY CO LTD

|

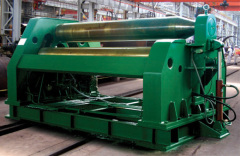

Sheet rolling machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sheet rolling machine

New style Digit type manual crowning conveniently mounted on the right side of the bed enabling operator to adjust simply by

Sheet rolling machine

Features

1. Hydraulic / Mechanical ram, synchronised positive stop design, ram stroke controlled by precision mechanical nut depth stops built into each cylinder. Electronically controlled by ENC-18 Programmable digital controller assuring accurate repeatability.Parallelism is ensured by torsion bar that can be easily adjusted by clutch system.

2. New style Digit type manual crowning conveniently mounted on the right side of the bed enabling operator to adjust simply by rotating the dial whilst the analogue digit system indicates the amount of movement

3. Segmented heavy duty 86° offset top punch is segmented for return bend clearance and incorporates a safety key to stop punch dropping.

4. Multi vee ('V') bottom die is made from solid die block design to handle heavy plate, safety edge vee ('V') is incorporated in bottom die block.

5. Conveniently mounted control box on pendant for quick swivel and adjustments.Enclosed rear gate with micro safety switches complete with sliding rear door for easy access.

6. Sliding steel fabricated sheet supports enabling a wide range of material sizes to be aligned and supported at the correct required height. This feature is achieved with a 'T' slot machined down the total length of the die bed; sheet supports are also adjustable vertically to assist in supporting material with return bends already folded.

7. Adjustable sliding blocks control the machines beam to provide desirable open height distance to the (slow speed) mute bending point. Operator adjustable locking knobs for quick adjustment, enables accurate repeatability and increased productivity.

8. Metal safety guarding surrounding the machine with rear sliding door fitted and micro switch ensuring operator safety. Clear access panels placed at each end of machine allows the operator to clearly view tooling and work piece during bending operation. Metal master specially design gates to suit safety requirements.

9. Hydraulic MPA pressure gauge mounted on right side of support frame with quick adjusting pressure control knob allowing operator to accurately set the pressure required for different material thickness, incorporating with hydraulic overload protection.

10. Welded steel fabricated synchronised torsion bar horizontally supporting main bending beam to provide consistent parallelism that also can be adjusted for taper correction. The vertical supporting slides are treated to provide greater ware resistance and increased accuracy.

11. Reinforced side frames providing addition support strength to machine throat

Features

1. Hydraulic / Mechanical ram, synchronised positive stop design, ram stroke controlled by precision mechanical nut depth stops built into each cylinder. Electronically controlled by ENC-18 Programmable digital controller assuring accurate repeatability.Parallelism is ensured by torsion bar that can be easily adjusted by clutch system.

2. New style Digit type manual crowning conveniently mounted on the right side of the bed enabling operator to adjust simply by rotating the dial whilst the analogue digit system indicates the amount of movement

3. Segmented heavy duty 86° offset top punch is segmented for return bend clearance and incorporates a safety key to stop punch dropping.

4. Multi vee ('V') bottom die is made from solid die block design to handle heavy plate, safety edge vee ('V') is incorporated in bottom die block.

5. Conveniently mounted control box on pendant for quick swivel and adjustments.Enclosed rear gate with micro safety switches complete with sliding rear door for easy access.

6. Sliding steel fabricated sheet supports enabling a wide range of material sizes to be aligned and supported at the correct required height. This feature is achieved with a 'T' slot machined down the total length of the die bed; sheet supports are also adjustable vertically to assist in supporting material with return bends already folded.

7. Adjustable sliding blocks control the machines beam to provide desirable open height distance to the (slow speed) mute bending point. Operator adjustable locking knobs for quick adjustment, enables accurate repeatability and increased productivity.

8. Metal safety guarding surrounding the machine with rear sliding door fitted and micro switch ensuring operator safety. Clear access panels placed at each end of machine allows the operator to clearly view tooling and work piece during bending operation. Metal master specially design gates to suit safety requirements.

9. Hydraulic MPA pressure gauge mounted on right side of support frame with quick adjusting pressure control knob allowing operator to accurately set the pressure required for different material thickness, incorporating with hydraulic overload protection.

10. Welded steel fabricated synchronised torsion bar horizontally supporting main bending beam to provide consistent parallelism that also can be adjusted for taper correction. The vertical supporting slides are treated to provide greater ware resistance and increased accuracy.

11. Reinforced side frames providing addition support strength to machine throat

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Rolling Machine

Thread Rolling Machine

Steel Rolling Machine

Plate Rolling Machine

Hydraulic Rolling Machine

Rolling Bag Making Machine

More>>

.jpg)