|

NANTONG JUGAO MACHINERY CO LTD

|

stainless steel sheet bender

| Price: | 5000.0~100000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

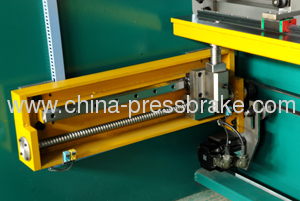

1.stainless steel sheet bender

The synchronization of the press brake adopts the technology of full loop electro hydraulic servo control,

stainless steel sheet bender

The synchronization of the press brake adopts the technology of full loop electro hydraulic servo control, the positioning signal of the ram is feed back by optical encoder to the CNC system, which controls the opening size of the synchronizing valves and adjusts the oil inlet amount of the oil cylinders, to realize the synchronizing movements of the ram ( Y1, Y2), and keep the worktable always in parallel situation.

Introduction of each axis of press brake

Y upward – downward of cylinder

Y1 upward – downward of left cylinder

Y2 upward – downward of right cylinder

X forward – backward of back gauge

X1 forward – backward of left finger on back gauge

X2 forward – backward of right finger on back gauge

R upward – downward of back gauge

R1 upward – downward of left finger on back gauge

R2 upward – downward of right finger on back gauge

Z leftward – rightward of back gauge

Z1 leftward – rightward of left finger on back gauge

Z2 leftward – rightward of right finger on back gauge

W mechanical crowning of worktable

V hydraulic crowning of worktable

3 + 1 axis: Y1, Y2, X, W/V

4 + 1 axis: Y1, Y2, X, R, V

6 + 1 axis: Y1, Y2, X, R, Z1, Z2, V

8 + 1 axis: Y1, Y2, X1, X2, R1, R2, Z1, Z2, V

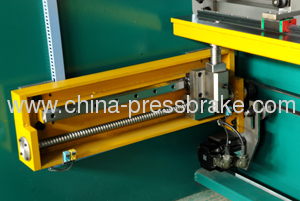

The synchronization of the press brake adopts the technology of full loop electro hydraulic servo control, the positioning signal of the ram is feed back by optical encoder to the CNC system, which controls the opening size of the synchronizing valves and adjusts the oil inlet amount of the oil cylinders, to realize the synchronizing movements of the ram ( Y1, Y2), and keep the worktable always in parallel situation.

Introduction of each axis of press brake

Y upward – downward of cylinder

Y1 upward – downward of left cylinder

Y2 upward – downward of right cylinder

X forward – backward of back gauge

X1 forward – backward of left finger on back gauge

X2 forward – backward of right finger on back gauge

R upward – downward of back gauge

R1 upward – downward of left finger on back gauge

R2 upward – downward of right finger on back gauge

Z leftward – rightward of back gauge

Z1 leftward – rightward of left finger on back gauge

Z2 leftward – rightward of right finger on back gauge

W mechanical crowning of worktable

V hydraulic crowning of worktable

3 + 1 axis: Y1, Y2, X, W/V

4 + 1 axis: Y1, Y2, X, R, V

6 + 1 axis: Y1, Y2, X, R, Z1, Z2, V

8 + 1 axis: Y1, Y2, X1, X2, R1, R2, Z1, Z2, V

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Sheet Stainless Steel

Stainless Steel Sheet

Expanded Stainless Steel Sheet

Perforated Stainless Steel Sheet

Stainless Steel Coil Sheet

Stainless Steel Plate Sheet

More>>

.jpg)