|

NANTONG JUGAO MACHINERY CO LTD

|

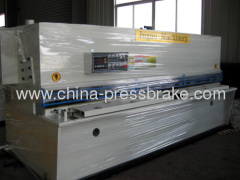

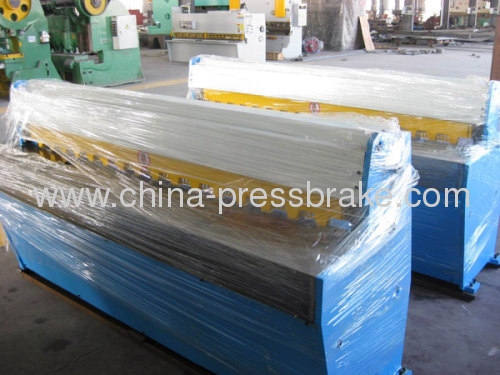

sheet metal guillotine shear

| Price: | 6000.0~100000.0 USD |

| Payment Terms: | T/T,L/C, |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.CNC CONTROL IN BACK STOP

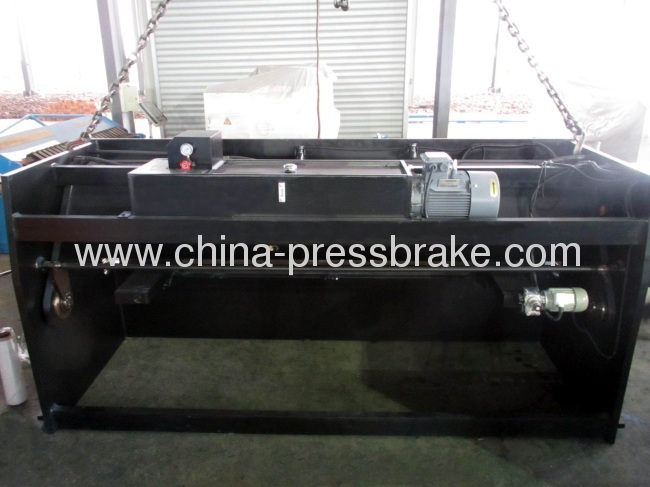

Steel-welded construction, vibration to eliminate stress with high strength and good rigidity

1.Steel-welded construction, vibration to eliminate stress with high strength and good rigidity

2.Advanced technology

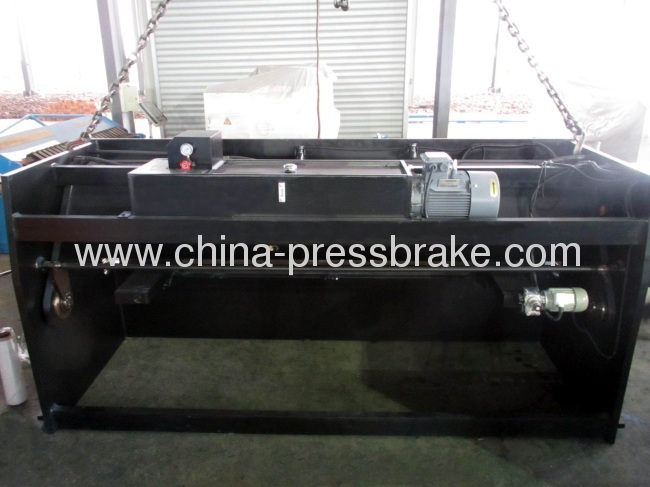

2-1,adopted advanced hydraulic system reduced the pipe joints steadiness and reliability

2-2,oil cylinder fitted in series to avoid the cutting angle change while shearing the plate.

2-3,the setting surface of upper blade is screw this keep homogeneity of blade clearance while shearing the plate.

2-4,energy accumulator for stroke's returning back.

2-5,upper and lower balde is rectangle which material is 6CrW2Si ,with good hardness and long age.

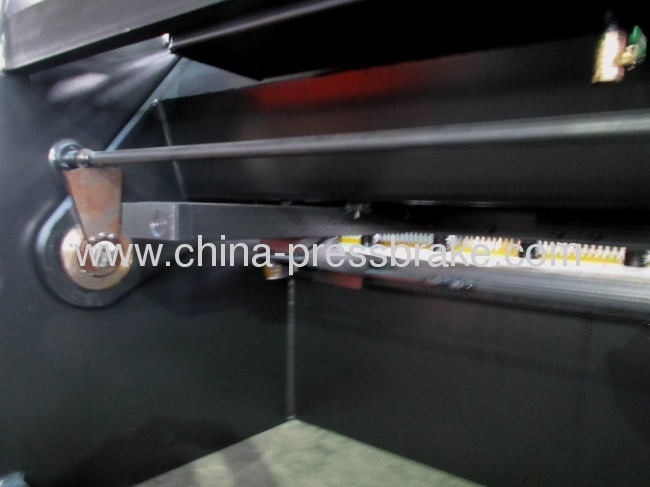

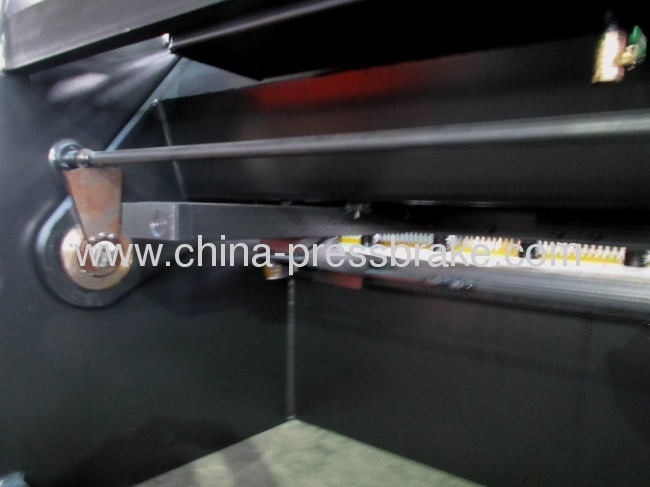

2-6,the blade clearance can adjusted by hand wheel and the number marked on the plate. Adjust quickly and easily with good credibility.

2-7,blade stroke adjusted stepless, the pressure can adjusted according to the thickness automatically.

2-8,it has equipped with light to overlapping the draw line on the plate.Gauge size and cutting times adopt staff counter ,operate very easy.

2-9,protective grating controlled by electrical system.

2-10,support device with ball to reduce the damage of the board.

2-11,oil cylinder used No 45 steel substrate inside hole boring precise.

2-12, piston rod: used No 45 steel substrate plating Chromium outside.

3.CNC systems:

Imported Holland DELEM or Domestic cnc systems ,along with ball screw and servo motor for backgauge,higher accuracy will be achieved .

2.Advanced technology

2-1,adopted advanced hydraulic system reduced the pipe joints steadiness and reliability

2-2,oil cylinder fitted in series to avoid the cutting angle change while shearing the plate.

2-3,the setting surface of upper blade is screw this keep homogeneity of blade clearance while shearing the plate.

2-4,energy accumulator for stroke's returning back.

2-5,upper and lower balde is rectangle which material is 6CrW2Si ,with good hardness and long age.

2-6,the blade clearance can adjusted by hand wheel and the number marked on the plate. Adjust quickly and easily with good credibility.

2-7,blade stroke adjusted stepless, the pressure can adjusted according to the thickness automatically.

2-8,it has equipped with light to overlapping the draw line on the plate.Gauge size and cutting times adopt staff counter ,operate very easy.

2-9,protective grating controlled by electrical system.

2-10,support device with ball to reduce the damage of the board.

2-11,oil cylinder used No 45 steel substrate inside hole boring precise.

2-12, piston rod: used No 45 steel substrate plating Chromium outside.

3.CNC systems:

Imported Holland DELEM or Domestic cnc systems ,along with ball screw and servo motor for backgauge,higher accuracy will be achieved .

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Sheet Metal Guillotine

Guillotine Shear

Sheet Metal Shear

Pneumatic Sheet Metal Shear

Hydraulic Guillotine Shear

Mechanical Guillotine Shear

More>>

.jpg)