|

NANTONG JUGAO MACHINERY CO LTD

|

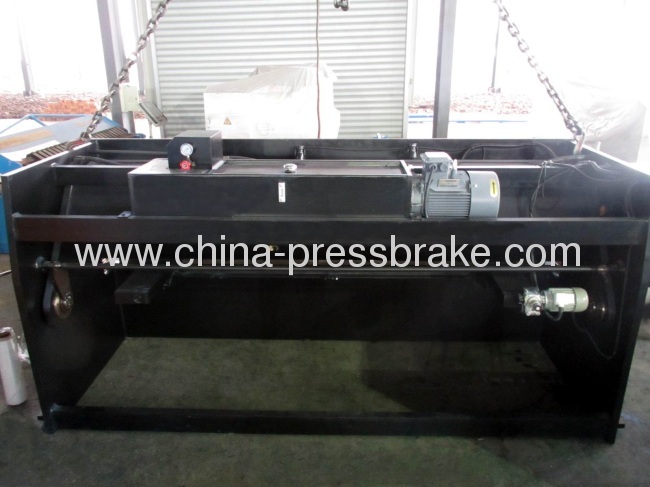

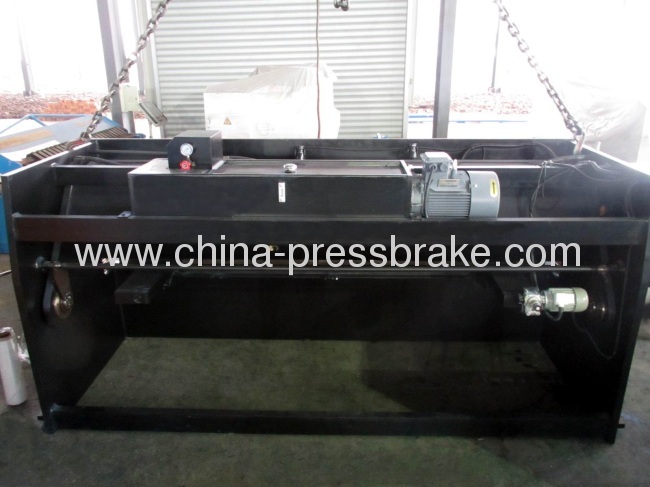

shear machines QC11Y- 12X8000

| Price: | 5000.0~200000.0 USD |

| Payment Terms: | T/T,L/C, |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No: QC11Y-12X8000

The metal sheet is moved easily by the rolling balls and the support block located on the table to ensure the surface quali

1. The metal sheet is moved easily by the rolling balls and the support block located on the table to ensure the surface quality of the sheet to be cut. There are front support arms and side squaring arm.

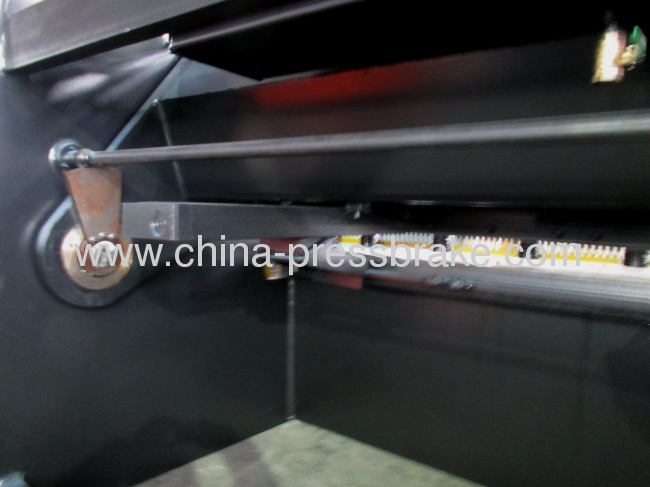

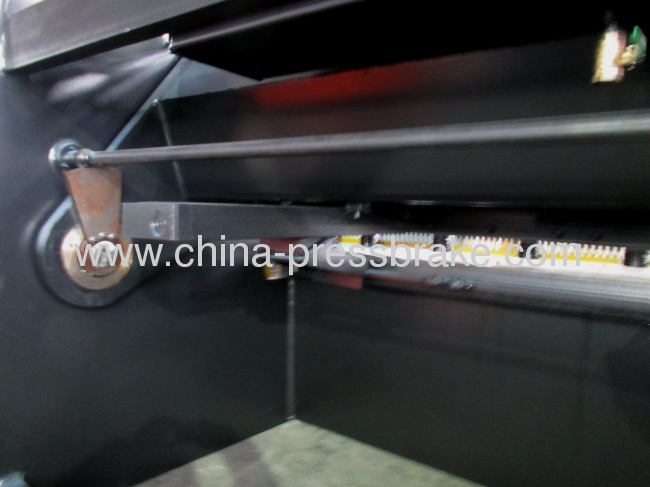

2. Closed loop control system is composed of NC controller and the encoder. NC controller has the automatic function of inspection and compensation. The back gauge is driven by DC servo motor, the positioning precision of the back gauge, the parallelism of the sheet to be cut off and the precision of the shear size can be ensured. After inputting precomputed data, the back gauge can be automatically moved, positioned, stopped and retraction when cutting. X axis repeat positioning accuracy: 0. 1mm.

3. Protective fence and the safety interlocker to ensure the operation safety. Power supply switch that is set in the electric box will be automatically turned off when the box's door is opened or the fence is turned up. Protecting barrier with safety interlocker is mounted on the back of the machine. Another, there are travel limit protection and foot pedestal mounted emergency off switch.

2. Closed loop control system is composed of NC controller and the encoder. NC controller has the automatic function of inspection and compensation. The back gauge is driven by DC servo motor, the positioning precision of the back gauge, the parallelism of the sheet to be cut off and the precision of the shear size can be ensured. After inputting precomputed data, the back gauge can be automatically moved, positioned, stopped and retraction when cutting. X axis repeat positioning accuracy: 0. 1mm.

3. Protective fence and the safety interlocker to ensure the operation safety. Power supply switch that is set in the electric box will be automatically turned off when the box's door is opened or the fence is turned up. Protecting barrier with safety interlocker is mounted on the back of the machine. Another, there are travel limit protection and foot pedestal mounted emergency off switch.

shearing machine4.the back gauge is controlled by E20 or DA-250 control system5. it is possible that gap between top and bottom blades could be automatic adjusted through control system.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.jpg)